Case Studies

Proven Performance Across the Platform

Real Results from Critical Facilities' Projects

Baptist Hospital

Chiller Plant Optimization

Chiller Optimization

When Baptist Hospital’s chillers were not operating at optimal capacity. After loud and unstable conditions emerged, and a surge condition was detected, ThermaServe was called in to correct the chiller plant problems and increase energy efficiency for this critical care facility.

2 Chillers Optimized | 1.23 Year Payback | 750-Ton Chiller Pump Piping

Baptist Hospital’s chillers were not operating at optimal capacity. After loud and unstable conditions emerged and a surge condition was detected, ThermaServe was called in to correct the chiller plant problems and increase energy efficiency for this critical care facility.

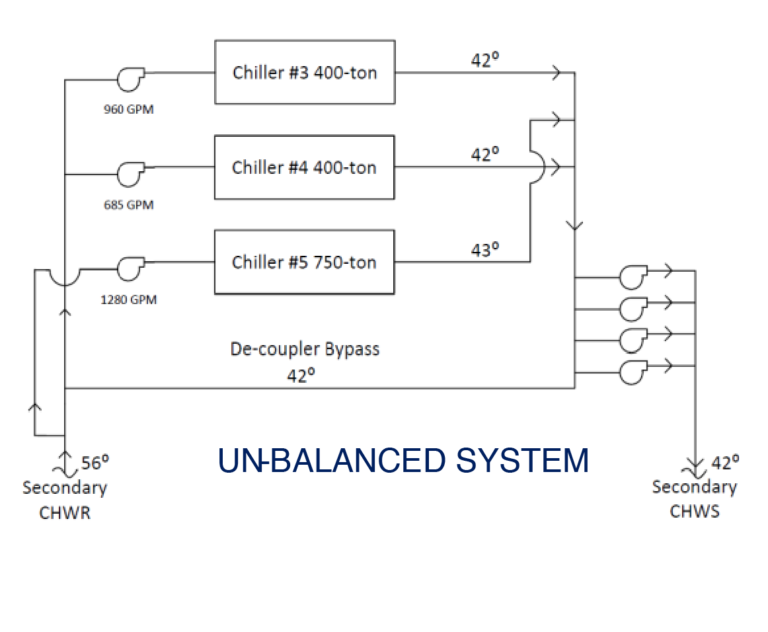

When both centrifugal chillers were operating, the 750-ton chiller return temperature was the same as the return secondary water temperature, but at the same time, the return water temperature to the 400-ton chiller was at a lower mixed water temperature. This condition caused the 400-ton chiller to operate at a much lower percentage of design load than the 750-ton chiller. The York 400-ton constant speed centrifugal chiller runs inefficiently at low loads. If this chiller was variable speed, it would operate very efficiently at low loads.

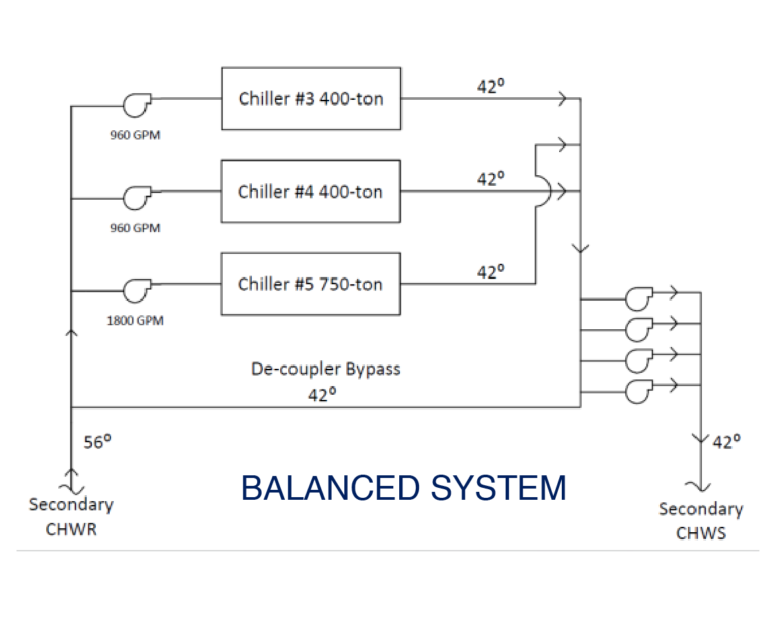

We relocated the 750-ton chiller chilled water return pipe connection from the secondary loop chilled water return to the primary loop chilled water return. We reconfigured the primary chilled water pumps to provide 2.4 gallons per minute per ton and replaced the solid-state starter for the 400-ton chiller with a variable speed drive. We supervised building automation personnel in reprogramming the chiller plant control system for optimal chiller staging and condenser water temperature control.

Baptist Health Pavilion Health Services

Plumbing Renovation

Plumbing Renovation

When Baptist Health converted a former retail space into a new outpatient care center, ThermaServe delivered a complete plumbing system renovation—including a specialized vacuum system installation—to meet healthcare standards, eliminate floor trenching, and ensure an on-time, disruption-free facility launch.

On-time Completion | O Change Orders | 1 Acorn Sanitary Vacuum System

A large part of the mechanical scope was the need for a full plumbing renovation to meet the complex clinical needs of a healthcare environment, including water savings, infection control, and construction schedule constraints.

Adding complexity was the specification of an Acorn sanitary vacuum system, an advanced plumbing technology requiring specialized installation of nonconventional appliances and valves.

ThermaServe was contracted to provide and install the full commercial plumbing system, including:

- Sanitary waste and vent

- Domestic hot and cold water distribution

- Specialty installation of an Acorn sanitary vacuum system

- Coordination with general contractor and other trades

- Project completion on a fast-tracked schedule

Our team managed the installation of both conventional and specialized plumbing components with zero disruption to other trades or project deadlines. The vacuum plumbing system eliminated the need for floor trenching and cutting—saving time, reducing dust and debris, and improving infection control compliance during construction.

We also leveraged our healthcare experience to ensure the system was installed for long-term reliability and water conservation in a patient-focused environment.

- Zero Change Orders

- On-Time Completion

- Eliminated Floor Trenching with Vacuum Technology

- Enhanced Water Efficiency

This successful installation as per the design plans and specifications delivered long-term reliability, and enabled Pavillion Health Services and Baptist Health to open their new primary care facility on schedule.

Washington Hospital Center

Washington, D.C.

Boiler Upgrade

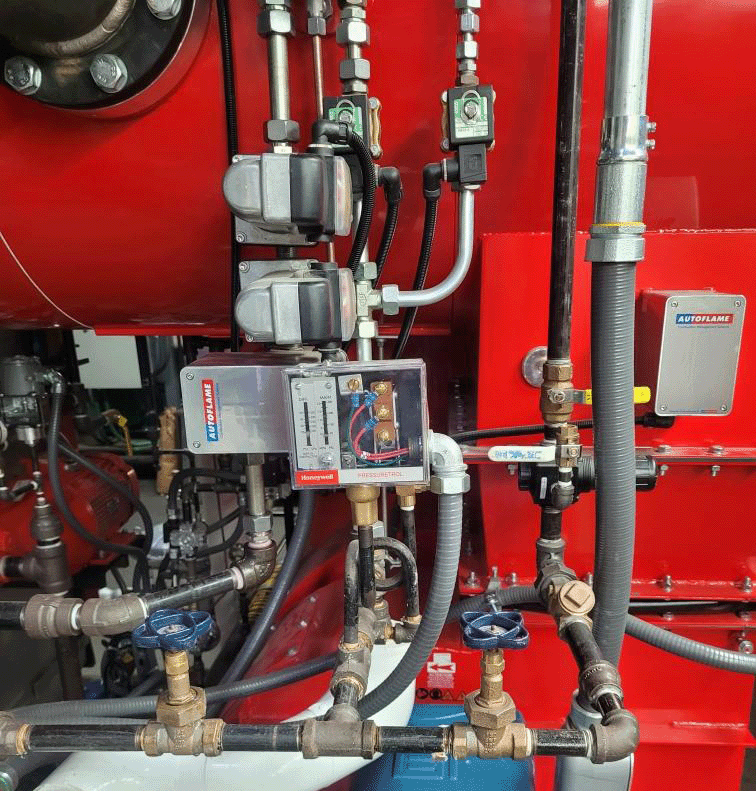

ACI developed a comprehensive solution for Washington Hospital Center to bring their six boilers into compliance and set the stage for a greener future.

Upgrade Boilers and Improve Emissions Levels

The Washington Hospital Center, a 900-bed hospital, serves as the flagship hospital for MedStar Health and is one of the largest medical centers in Washington, D.C. The facility is the referral center for patients with complex conditions, as well as a safety-net hospital. A central plant supports the entire medical center campus.

When Washington Hospital Center wanted to launch a transformative project to upgrade all six boilers in their central plant, they engaged ACI to tackle this daunting challenge. The existing equipment, dating back to 1955, was not only outdated but also failing to meet new emissions regulations. Given their age, the burners were not loading oxygen properly, resulting in emissions that were above the limits set by the D.C. government. ACI’s team of experts rose to the challenge and developed a comprehensive solution that not only brought the boilers into compliance with the latest regulations but also set the stage for a greener future.

Due to the hospital’s 24/7 operations and the need for boiler redundancy, a completeshutdown of the boilers during the improvement project was not a viable option. It was essential that a phased approach be implemented to eliminate disruptions to patient care and ensure that each boiler was fully commissioned before work on the next boiler began. ACI developed a plan to upgrade all six boilers at the client’s site while also maintaining redundancy, in accordance with hospital policy, to ensure that the upgraded boilers were commissioned before starting on the next upgrade.

Due to the hospital’s 24/7 operations and the need for boiler redundancy, a completeshutdown of the boilers during the improvement project was not a viable option. It was essential that a phased approach be implemented to eliminate disruptions to patient care and ensure that each boiler was fully commissioned before work on the next boiler began. ACI developed a plan to upgrade all six boilers at the client’s site while also maintaining redundancy, in accordance with hospital policy, to ensure that the upgraded boilers were commissioned before starting on the next upgrade.

ACI’s certified team split the project into two phases, upgrading the winter-use boilers in the summer and summer-use boilers in the winter, to eliminate any downtime and ensure that hospital operations could continue around the clock.

It was crucial for the hospital to find a partner who could manage the project in a manner that would ensure continuity of operations for the hospital and ultimately patient care. Because of ACI’s exceptional service and achievements in the first phase of this project, Washington Hospital has entrusted ACI with continuing the upgrading of their boilers. ACI’s phased off-season approach ensures minimum disruption to the hospital’s operations and ensures the facilities continue to run smoothly.

It was crucial for the hospital to find a partner who could manage the project in a manner that would ensure continuity of operations for the hospital and ultimately patient care. Because of ACI’s exceptional service and achievements in the first phase of this project, Washington Hospital has entrusted ACI with continuing the upgrading of their boilers. ACI’s phased off-season approach ensures minimum disruption to the hospital’s operations and ensures the facilities continue to run smoothly.Johns Hopkins Medicine Facilities

Retro-Commissioning Rebates

Retro-Commissioning

Under the BGE Smart Energy Savers Program®, GFS provided full retro-commissioning (RCx) services at three Johns Hopkins Medicine (JHU Medicine) facilities, resulting in BGE RCx rebates of $15,000 per facility as well as ongoing energy savings.

RCx services were performed throughout more than 245,000 sq. ft. of building space at Johns Hopkins Health Care and Surgery Center, Green Spring Station Pavilions I and II in Lutherville, Maryland, and at the Johns Hopkins Health Care and Surgery Center in White Marsh, Maryland.

The Retro-Commissioning Plan

- Optimize energy efficiency of existing building HVAC systems

- Reduce electrical energy consumption where possible

- Minimize tenant interruption and maximize occupant satisfaction

GFS provided turn-key retro-commissioning services, including facility audits to identify deficiencies, a retro-commissioning plan, and project management.

Implementation of recommended measures, including:

- Maximize Free Cooling via Rooftop Unit Economizers

- Limit Control Range of Thermostats

- Correct Restricted Return Air Ductwork

- Demand Ventilation/IAQ Function for Rooftop Units

- Air Balancing of HVAC System

- Control System Commissioning

Results By the Numbers

- $45,000 in BGE rebates

- $56,000 in annual energy savings

- 245,000 sq ft of service area

Walter Reed Army Medical Center

Bethesda, MD

Steam Solution

When critical boiler failures threatened steam service to the hospital, ACI rapidly installed temporary boilers to keep operations running while long-term repairs were underway.

Walter Reed National Military Medical Center is the premier military medical facility in the United States. Known for providing world-class care to service members, veterans, and U.S. Presidents, Walter Reed is a critical part of the Department of Defense’s healthcare system—where reliable facility infrastructure is essential to mission readiness and patient care.

During the final phases of the Walter Reed Army Medical Center’s transition and consolidation process, the facility faced a critical need for temporary steam production. The on-site boilers—vital for heating, sterilization, and essential hospital functions—were being decommissioned as part of the broader Base Realignment and Closure (BRAC) initiative. With limited redundancy and no tolerance for downtime in a healthcare environment, Walter Reed needed a rapid-response partner to install temporary boilers that would ensure seamless operations until permanent systems were reestablished elsewhere on the campus.

American Combustion Industries (ACI), an Exigent company, responded swiftly with a turnkey temporary boiler solution. ACI provided four 2,391 HP mobile boiler rooms equipped with high-pressure steam boilers rated at 82,500 lbs/hr, feedwater systems, and safety devices. The total maximum output of this solution is 330,000 lbs/hr or 9,564 boiler hp. The scope included full design, coordination, and installation of temporary piping, fuel supply, and electrical connections—all configured to integrate with the hospital’s existing steam distribution system.

ACI’s experienced team worked closely with Walter Reed’s facilities department and project stakeholders to ensure installationmet both hospital operational requirements and strict Department of Defense standards. By leveraging our union-trained technicians and deep expertise in critical systems, we completed installation and commissioning within a compressed timeframe.

ACI’s rapid deployment allowed Walter Reed to maintain uninterrupted steam service throughout the transition period, protecting patient care and critical facility operations.

Our solution ensured:

- 24/7 steam availability during the decommissioning of permanent boilers

- Seamless integration with hospital infrastructure

- Compliance with federal and military facility standards

- Zero disruption to hospital operations during installation

This project exemplified ACI’s commitment to delivering responsive, high-quality service for mission-critical facilities—especially when failure isn’t an option.