Case Studies

Proven Performance Across the Platform

Real Results from Critical Facilities' Projects

IKEA

College Park, Maryland

Stormwater Retrofit

When IKEA’s largest superstore in the D.C. region had a stormwater retention emergency, they called on JPG Services to help.

Built in 2003 on 45 acres off Route 1 at Interstate 95 in College Park, Md., IKEA’s high-performing superstore is the third and largest IKEA store in the region, featuring multiple showrooms, a restaurant in-store, with surrounding retail and office space in the mixed-use zoning around the store. The 340,000 square-foot store, built in IKEA’s signature big-box, stand-alone warehouse style in distinctive bright blue and yellow exterior, supports its many customers with a large asphalt parking lot — and also happens to be adjacent to a United States Department of Agriculture (USDA) Conservation area, home to many local animals including several species of beavers and several species of important migratory birds. The potential for runoff from the asphalt parking structure into the protected conservation area was a significant concern for IKEA, a company known for its sensitivity to environmental issues.

Adding to runoff concerns, IKEA’s on-site stormwater retention structure became prone to blockages at the low-flow outlet, resulting in catastrophic surcharges — and expensive repair projects to clear up the problem. Outlet pipe clogs were not detectable without a site visit, and were only cleared by pumping out millions of gallons of water caused by the blockage.

After two years of consistent clogs and costly emergency repairs, IKEA turned to JPG Services, the D.C. metropolitan area’s leading experts in commercial HVAC, industrial VAC, and plumbing solutions, to diagnose the problem and design a solution to what had become a $40k expense to mitigate clogs — with no permanent solution identified.

JPG Services implemented a traditional repair — pumping out gallons of excess water — to allay the immediate risk of runoff and potential environmental damage. Then JPG went to work diagnosing the issue and identifying a long-term, efficient solution. With decades of experience providing organizations with budget-saving remediation to serious stormwater management issues, JPG Services immediately identified the downsides of any short-term solutions, including costly visits to inspect water levels, and more than likely, annual emergency pumping. And, if IKEA only acted to comply with annual inspections, there was a significant risk of a full tank and trash going over the overflow wall.

JPG Services Director of Industrial VAC, John Davis immediately identified a preventative solution that would save IKEA thousands of dollars, and give IKEA peace of mind that the USDA conservation area would be protected from any runoff damage such as sand and debris infiltrating streams and water systems.

The ideal—and cost-effective — solution? A unique industrial VAC product developed by JPG called TankVisionSM. This revolutionary product, offered only by JPG Services and in the process of being registered as a service mark, uses telemetry to allow JPG Services technicians a clear view of the tank. Monitored remotely by computer, alarm points are established TankVisionSM gives JPG technicians a daily view of the tank water level so that quick action can be taken if the water level rises above zero, and maintains water systems in good operating condition so that sand and debris do not infiltrate streams and water systems. Without clear vision into the tank? Costly visits to inspect water levels, and more than likely, annual emergency pumping. And, if IKEA only acted to comply with annual inspections, there is a significant risk of a full tank and trash going over the overflow wall.

Scope of Services

The outlined scope of services, including monitoring the TankVisionSM system, to mitigate outstanding clog issues and prepare the IKEA site for the installation of TankVisionSM included:

- Pump 5 million gallons of stormwater to allow for safe, confined space entry into the structure.

- Clear the outlet blockage and re-establish normal flow.

- Install a TankVisionSM storm level monitor near the outlet and begin continuous monitoring of the structure’s performance.

- Monitor stormwater levels via TankVisionSM system remotely at a once and hour frequency, with alarm points set to trigger texts/emails alerting JPG of a potential emergency issues.

IKEA has benefited significantly from the TankVisionSM system’s most important feature: prevention. After more than a year of remote monitoring, JPG Services technicians began to observe data indicating a low-flow blockage and an increase in latent stormwater retention. The system was no longer fully discharging stormwater from the structure — and because the monitor has been in place, this condition was noticed long before an expensive remediation project was required or damaging runoff reached the USDA Conservation site. The potentially disastrous situation was resolved with a quick confined space entry to clear the outlet pipe to restore proper flow.

With the TankVisionSM system still in place at the IKEA store site, and with experienced JPG technicians tracking and monitoring water flow levels, tank performance is maintained in optimal condition. And when the water level does increase, indicating drain blockages, JPG is able to remedy the situation early, saving IKEA up to 75% of an emergency, and much more significant, repair.

IKEA has benefited significantly from the TankVisionSM system’s most important feature: prevention. After more than a year of remote monitoring, JPG Services technicians began to observe data indicating a low-flow blockage and an increase in latent stormwater retention. The system was no longer fully discharging stormwater from the structure — and because the monitor has been in place, this condition was noticed long before an expensive remediation project was required or damaging runoff reached the USDA Conservation site. The potentially disastrous situation was resolved with a quick confined space entry to clear the outlet pipe to restore proper flow.

With the TankVisionSM system still in place at the IKEA store site, and with experienced JPG technicians tracking and monitoring water flow levels, tank performance is maintained in optimal condition. And when the water level does increase, indicating drain blockages, JPG is able to remedy the situation early, saving IKEA up to 75% of an emergency, and much more significant, repair.Six Flags America

Largo, Maryland

Chiller Start-up

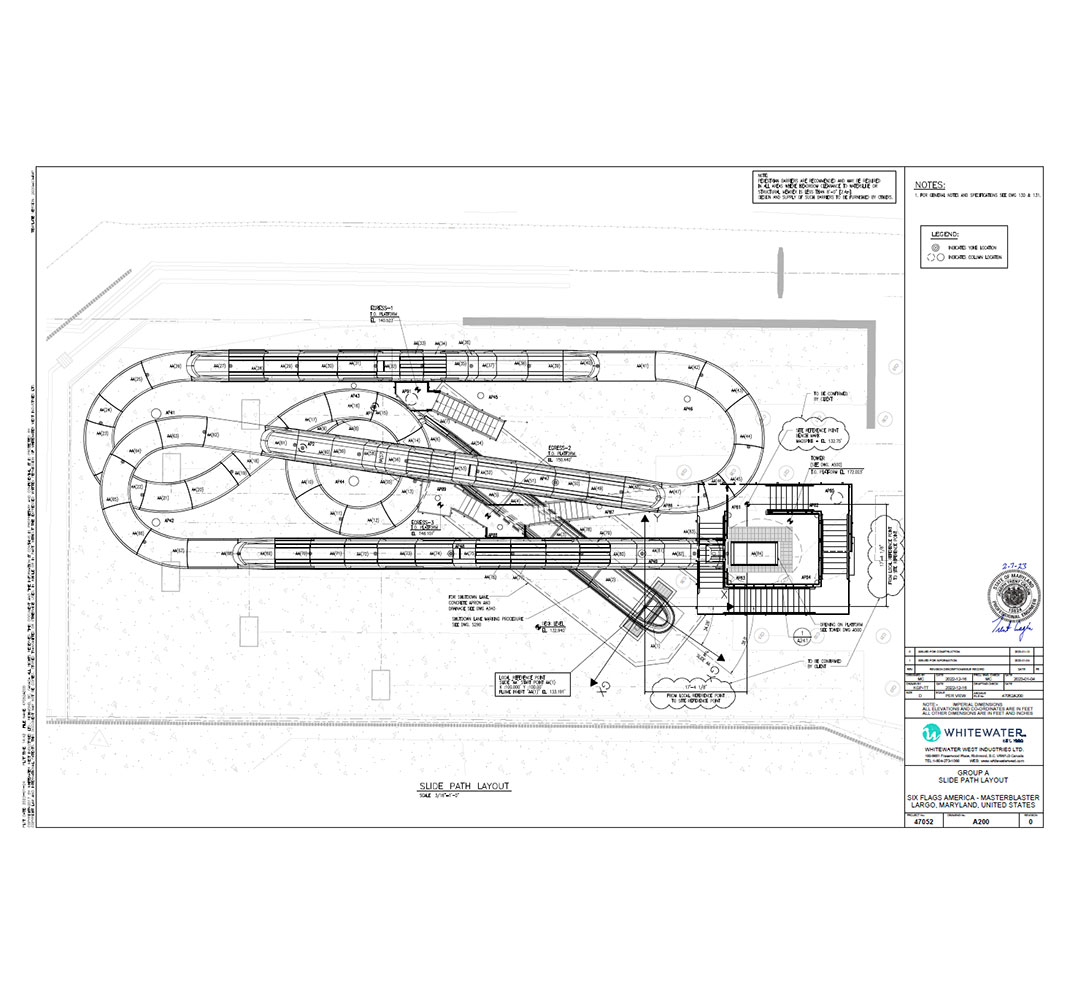

Six Flags America unveils the spectacular RipQurl Blaster water attraction, engineered by JPG's commercial plumbing pros!

In the summer of 2023, Six Flags America in Largo, Maryland, debuted their latest attraction, the RipQurl Blaster, the region’s tallest “Master Blaster Water Coaster,” and the park’s largest capital investment in over a decade. RipQurl Blaster is an innovative water coaster taking riders in a raft through three powerful uphill rip currents while zigzagging through 550 feet of twists and turns. The ride features three breathtaking drops, three AquaLucent hairpin turns, and a pitch-black wall-hugging helix finale before the final splashdown.

With such a large investment on the line, Six Flags needed to ensure that the new attraction was a refreshing and fun ride for the park’s thrill-seekers—and because it is a water ride, that its plumbing functionality operated safely and efficiently.

With JPG Services having performed VAC services work at Six Flags America prior to the Covid-19 pandemic, the operations staff at Six Flags was already impressed with the professionalism and customer service JPG technicians provided. JPG was asked to bid on the plumbing work for their new water coaster—and after walking the project and studying the plans and requirements, we submitted a bid to deliver an efficient and economical design to the project. Our detailed bid, as well as our extensive experience, expertise, and knowledge of complex commercial plumbing challenges, was the winning formula to be hired.

JPG technicians worked closely with park engineers and Six Flags staff to design a system that tied the new water attraction back to the park’s existing pump system, and to find the most effective products and procedures so that park patrons were not disturbed during the construction of the attraction and the attraction’s infrastructure. Working with the team at Six Flags, JPG ensured that the placement of our plumbing did not interfere with staff’s daily duties or customer traffic and flow.

JPG’s ability to work with the project’s engineering firm, as well as the Six Flags team, opened up lines of communication that helped JPG technicians to be more efficient with the project work. This open communication also helped JPG to move faster and gave them a clear scope of where the pumps, meters, and valves needed to be located, making it easier to check the valves and meters when the ride was being used on a daily basis.

Class A Office Building

Glendale, CA

Energy Optimization / BEPS Compliance

Global Facility Solutions (GFS) performed a highly successful retro-commissioning project at 800 N. Brand in Glendale, CA, which was recognized as the “Overall Winner” in the 2020 inaugural “Retro Rumble” competition hosted by The Energy Management Association (EMA) and ENERGY STAR.

Retro-Commissioning for Energy Efficiency Success

Project Objectives

- Improve energy efficiency of a 21-story, 527,338 sq ft office building

- Increase ENERGY STAR score

- Reduce Energy Use Intensity (EUI

- Optimize HVAC system performance

Scope of Work

- Conduct facility audit to identify system deficiencies

- Develop a comprehensive retro-commissioning plan

- Provide project management oversight of implementation

- Correct deficiencies in existing building systems

- Install operational enhancements to building automation and control system

Solutions

Comprehensive retro-commissioning services, including:

- Revision of day-to-day HVAC system operations

- Installation of new variable frequency drives for pumps and air handlers

- Control system upgrades to enhance energy management features

- Modifications to set-points, schedules, and energy management features

- Optimization of central cooling and heating system, including chillers, cooling towers, and individual air handlers

The retro-commissioning project, designed and implemented by GFS, delivered significant energy efficiency improvements and cost savings for the 800 N. Brand property, transforming it from a single-tenant headquarters to a high-performing, multi-tenant Class A office building.

Results By the Numbers

- ENERGY STAR score increased from 76 to 96 (20-point improvement)

- EUI score dropped from 70 to 34

- 527,338 rentable square feet of office space optimized

- 21 floors with individual air handling units improved

National Aquarium in Baltimore

Baltimore, MD

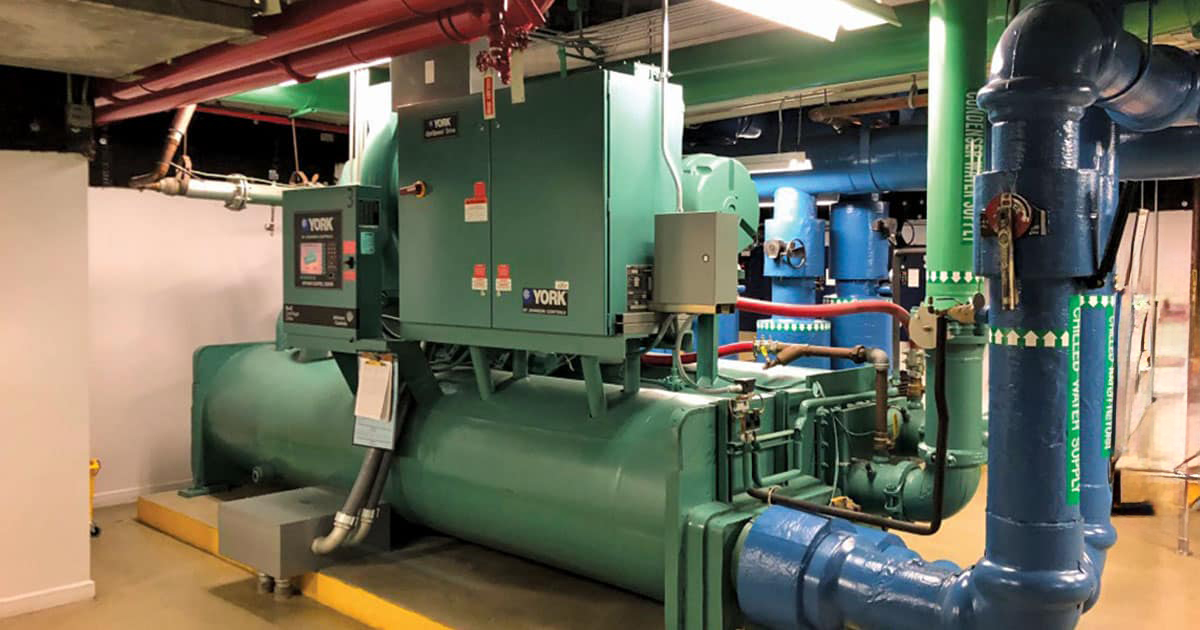

Central Plant Upgrade

Global Facility Solutions (GFS) provided engineering design services for the National Aquarium in Baltimore, MD, as part of a turn-key energy savings project implemented by Constellation, an Exelon Company. GFS created Mechanical/Electrical/Plumbing (MEP) engineering designs for the renovation and upgrade of the central chiller and boiler plants serving both the Pier 3 Aquarium and Pier 4 Pavilion facilities.

Energy Design for Energy Savings

Project Objectives

- Replace aging, inefficient HVAC equipment with modern, energy-efficient systems

- Ensure redundancy and reliability in the boiler plant for critical aquarium operations

- Achieve significant energy cost savings and utility incentives

Scope of Work

- Create MEP engineering designs for chiller and boiler plant upgrades

- Provide construction administration services

- Commission new systems and verify performance

Solutions

Comprehensive MEP engineering design services, including:

- Design of a free-cooling heat exchanger for winter operation

- Specification of high-efficiency chiller modules and condensing boilers

- Integration of variable speed pumps and DDC controls

- Production of permit drawings and energy savings analysis

- Construction administration, commissioning, and performance verification

The upgraded central plants, designed by GFS and implemented by Constellation, became operational in April 2015, delivering significant energy cost savings and improved reliability for the National Aquarium’s critical operations.

Results By the Numbers

- $80,900/year in energy cost savings

- $21,300 in utility incentives

- Replacement of two 200-ton chillers with six 70-ton variable speed chiller modules

- Replacement of three cast-iron boilers with five high-efficiency condensing boilers

600 13th St Office Building

Washington, DC

BEPS Compliance

Global Facility Solutions (GFS) provided engineering consulting services for 600 13th Street in Washington, DC, guiding the building owner through their first compliance cycle with The District’s Building Energy Performance Standard (BEPS) Program. This program is part of DC’s initiative to achieve citywide energy and greenhouse gas reduction targets of 50% by 2032.

DC Building Energy Performance Standard (BEPS) Compliance

Project Objectives

- Assist building owner with DC BEPS pathway selection

- Provide engineering expertise focusing on building operations and energy conservation

- Identify Energy Conservation Measures (ECMs) to reduce energy consumption at the property

- Ensure compliance with DC BEPS Program requirements

Scope of Work

- ENERGY STAR Portfolio Manager review to ensure accurate reporting

- Complete an ASHRAE Level 2 Energy Audit to identify ECMs at the property

- Review ECMs with building owner and property team and create an implementation plan

- Assist property owner with navigating DC BEPS Compliance Cycle

Solutions

Comprehensive engineering consulting services, including:

- ASHRAE Level 2 Energy Audit to determine cost-effective pathway for DC BEPS program compliance

- Development of tailored Energy Conservation Measures based on building features, tenant profiles, and systems setup

- Creation of implementation plan for identified ECMs

- Ongoing support for energy conservation project planning, funding, and execution

- Continued monitoring of energy savings project results in ENERGY STAR Portfolio Manager

- Assistance with submitting energy benchmarking results to DC Government per program guidelines

The engineering consulting services provided by GFS are enabling the property at 600 13th Street to navigate the DC BEPS compliance process effectively, identifying significant energy-saving opportunities and setting the stage for improved energy performance and reduced environmental impact.

Results By the Numbers

- Opportunities to reduce property baseline Energy Use Intensity (EUI) by 21.1%

- ECM Implementation plan projected to save 1,149,500 kWh per year

- Over 10 Energy Conservation Measures identified, including Chiller Plant Optimization and Lighting Retrofits