Case Studies

Proven Performance Across the Platform

Real Results from Critical Facilities' Projects

Omni Hotel

Jacksonville, Florida

Chiller Replacement

The Omni Hotel in Jacksonville, Florida needed to replace their aging penthouse chiller plant equipment, all while the hotel remained occupied. ThermaServe was able to complete a five-day install in only 16 hours—and provide energy savings of nearly a third of the annual cost per operating year.

3 Cooling Towers Replaced | 1 New Delta Controls DDC System | 2 500-Ton Chillers Modernized

The Omni Hotel in Jacksonville, Florida, needed to replace their aging penthouse chiller plant equipment, all while the hotel remained occupied. ThermaServe was able to complete a five-day install in only 16 hours—and provide energy savings of nearly a third of the annual cost per operating year.

The Omni Hotel in Jacksonville, Florida, a four-diamond, 16-floor luxury hotel, was built in the late 1980s. The Omni’s original 26-year-old penthouse chiller plant needed to be replaced with more efficient equipment, and the chillers contained CFC ozone-depleting refrigerant and were very loud, hindering the rental of penthouse suites.

The Omni Hotel in Jacksonville, Florida, a four-diamond, 16-floor luxury hotel, was built in the late 1980s. The Omni’s original 26-year-old penthouse chiller plant needed to be replaced with more efficient equipment, and the chillers contained CFC ozone-depleting refrigerant and were very loud, hindering the rental of penthouse suites. Based on the survey and analysis performed by ThermaServe, we were able to specify the equipment necessary to replace the existing equipment for an energy-saving modernization. This included variable speed drives incorporated with a new cooling tower and new secondary chilled water pumps, along with two new quieter variable speed drive chillers.

Based on the survey and analysis performed by ThermaServe, we were able to specify the equipment necessary to replace the existing equipment for an energy-saving modernization. This included variable speed drives incorporated with a new cooling tower and new secondary chilled water pumps, along with two new quieter variable speed drive chillers.

Solution

Our solution was to provide two 500-ton variable-speed centrifugal chillers with ozone-friendly refrigerant. Next, we replaced the existing three cooling towers with one new three-cell stainless steel cooling tower with a greatly improved physical footprint and added six new pumps with variable-speed drive motors for efficient operation. The mechanical modernization also included new butterfly valves and piping reconfiguration for the new equipment. The solution also included connecting all the new equipment to the Delta Controls DDC building automation system with a condenser water outdoor wet bulb reset control program for optimized cooling tower fan operation.Scope of Services

The chiller plant replacement was undertaken with an occupied and running hotel. The majority of the work was performed during the cooler months of the year to reduce the impact on the hotel, and further preparation and smaller equipment replacements were performed before the week of demolition and heavy equipment crane lifting. We disassembled and removed the existing cooling tower system and one chiller, installed, and brought a new chiller on-line, then disassembled and removed the other chiller and still kept the hotel running. The cooling tower replacement was the critical element to maintaining cooling for the entire new system cut over. We allotted 24 hours of full downtime for the hotel for the cooling tower installation and only took a remarkable 16 hours to complete a five day install.In addition to greatly improved guest comfort, the projected chiller plant energy savings are 29% or nearly a third of the annual cost per operating year. This is in addition to the (one-time) JEA utility rebate projecting a less than 10-year payback for this nearly $1M chiller plant modernization project.

Westminster Woods

Jacksonville, Florida

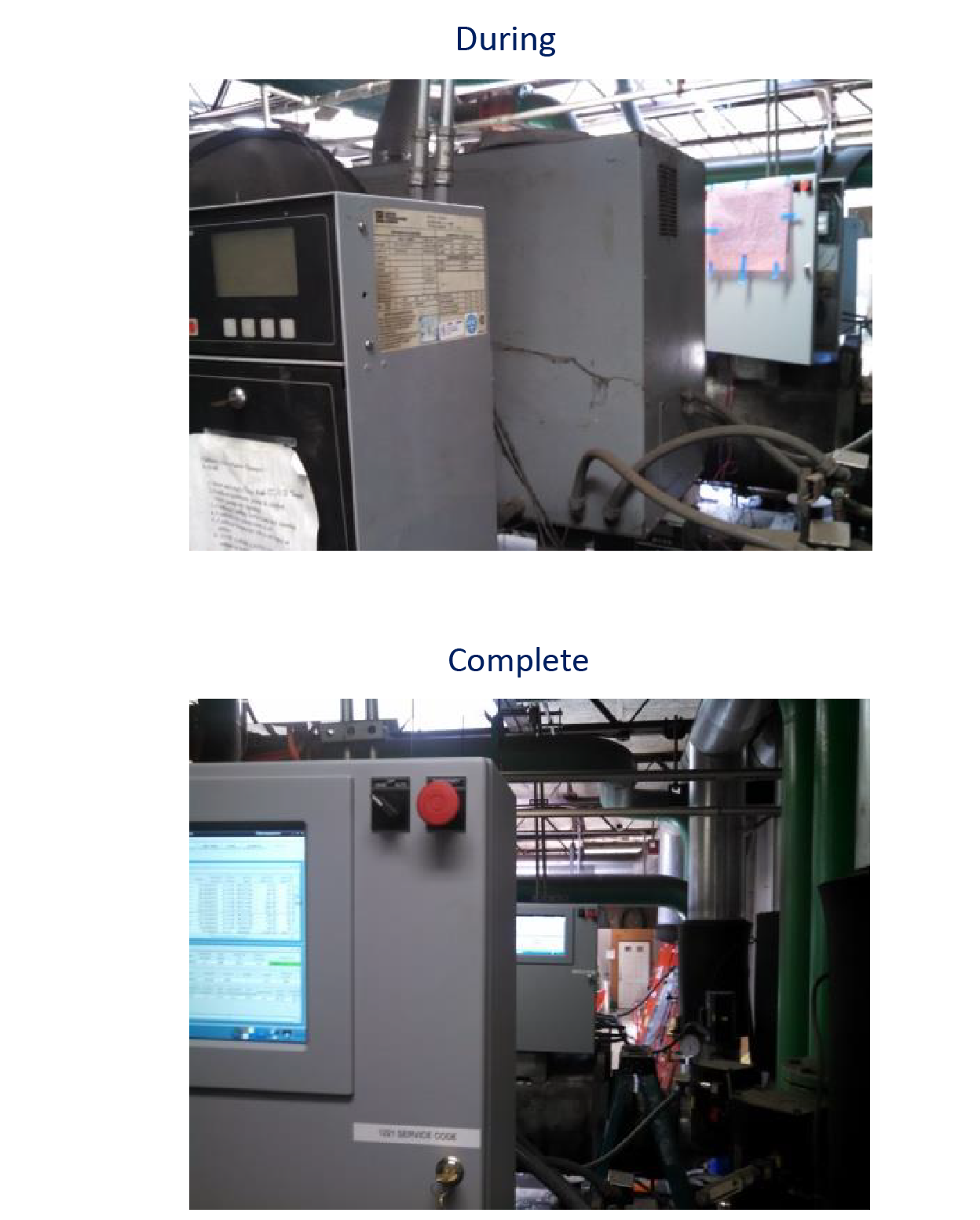

Chiller Modernization

The Westminster Woods on Julington Creek Retirement Community wanted to reduce risk, maximize efficiency, and realize savings by modernizing their chiller equipment—and chose ThermaServe to provide the solution.

2 300-Ton Chillers Modernized | 1 Touchscreen Display | 2 Chiller Lives Extended

The Westminster Woods on Julington Creek Retirement Community wanted to reduce risk, maximize efficiency, and realize savings by modernizing their chiller equipment—and chose ThermaServe to provide the solution.

Westminster Woods on Julington Creek, an upscale retirement community, needed a risk reduction and modernization plan for two 15-year-old chillers. ThermaServe was called on to assess the status of the aging chillers and provide a roadmap for modernizing the system.

To mitigate this challenge, we designed a solution that not only extended the overall life expectancy of the chillers but also delivered substantial cost savings. We rebuilt one compressor slide valve and replaced two obsolete Carrier PIC-1 control panels with advanced MCS control panels.

To mitigate this challenge, we designed a solution that not only extended the overall life expectancy of the chillers but also delivered substantial cost savings. We rebuilt one compressor slide valve and replaced two obsolete Carrier PIC-1 control panels with advanced MCS control panels.

Scope of Services

The scope was extensive. We replaced all existing wiring, including the starting panel, and installed new external sensors to replace the outdated ones to ensure a comprehensive overhaul. The introduction of a full touchscreen display with the MCS controls marked a leap forward in capabilities, exceeding the prior OEM control panel. This upgrade optimized efficiency and also promised to extend the life of the chillers by many years. The MCS controls, with their advanced features and full touchscreen display, not only contribute to operational efficiency but also lead to substantial utility cost savings. This successful modernization initiative will extend the useful life of the chillers by many more years, ensuring sustained performance excellence.

The MCS controls, with their advanced features and full touchscreen display, not only contribute to operational efficiency but also lead to substantial utility cost savings. This successful modernization initiative will extend the useful life of the chillers by many more years, ensuring sustained performance excellence.Malden Housing Authority

Malden, Massachusetts

Warranty Repairs

ATCO significantly reduces costs in a large housing complex by identifying factory defects in heat pump equipment and leveraging the manufacturer’s warranty.

Identifying a Cause and the Solution to Malfunctioning Heat Pumps

The Malden Housing Authority (MHA), an assisted/affordable housing provider in Malden, Massachusetts, preserves, extends, protects, creates, and expands public and affordable housing opportunities locally while maintaining and sustaining the affordability and improving the quality and condition of existing developments and units. In this endeavor, ATCO was hired to help support MHA’s facilities department, which manages over 43,000 units throughout the city of Malden.

After completing a recent energy project that replaced 172 mini-split heat pumps, ATCO technicians began to notice that condensing units were losing a lot of coils. The MHA needed to quickly identify the cause of this malfunction and a solution to restore heat pumps’ safety and functionality in MHA units.

ATCO inspected the heat pump wiring and noticed that they were losing a lot of coils in the condensing units. We were able to identify that the cause of the coil failure was a wire inside the unit that was laying on the condenser coil, causing the wire to chafe and then arc, which then resulted in a hole in the coil.

Solution

ATCO determined quickly that this malfunction was a factory defect and that they coil replacements were covered under the LG warranty. After ATCO contacted the local representative and arranged for LG to reimburse MHA for each heat pump experiencing the malfunction, our technicians inspected each unit to document the location of the wire and make any necessary changes to prevent the arcing.

Working closely with the MHA, the ATCO team was able to gain access to each unit in the housing authority quickly, thereby speeding up repairs. Upon completion of the project, all units were covered under the original warranty, and no additional coil replacements have been necessary.

Hilton

Springfield, Virginia

Emergency Hot Water

JPG’s quick response to Hilton’s urgent HVAC challenge and effective solution kept the hotel’s hot water running—and Hilton’s hotel guests happy.

The Hilton Springfield, first built in 1978 and last renovated in 2014, is a 12-story hotel located in Springfield, Virginia, a Washington, D.C. suburb near I-95 and the Capital Beltway I-495. The hotel is located across from Metro’s Springfield Station and is a quick drive to Washington, D.C., Ft. Belvoir, the Pentagon, and Arlington National Cemetery.

In May 2023, the Hilton Springfield experienced an HVAC emergency over the Memorial Day holiday weekend. With temperatures hovering above 90 degrees, the hotel’s original rooftop boiler finally gave out, after 60 years and only minimal maintenance performed on it. Supplying hot water to the entire 369-room hotel. If the boiler weren’t brought back online immediately, the entire hotel would be out of service due to a lack of hot water for the guest rooms.

Familiar with our reputation for prompt response times and expert, knowledgeable technicians, the Hilton Springfield turned to JPG Services to identify a fast, effective solution to the hotel’s emergency HVAC challenge. In addition to being known for their emergency response and reliability, JPG technicians are experts at choosing the right equipment and suppliers—essential when designing effective and efficient solutions.

Immediately addressing the off-hours emergency, JPG dispatched a technician to the property to diagnose the problem. When technicians were unable to fix the boiler, JPG drew on their ability to find the best suppliers and located a mobile boiler that same night. A technician was able to get the boiler back on temporarily while JPG assembled a group of technicians to install the new boiler the next morning.

JPG was able to quickly provide the Hilton Springfield with a new, more efficient boiler, saving the hotel thousands of dollars in energy costs and preventing a catastrophic shutdown of the hotel. In addition to energy savings, the new boiler and consistent JPG maintenance services will prevent future problems with hot water in the hotel’s guestrooms.

Congressional Towers Apartments

Rockville, MD

Flood Recovery

ACI mobilized to quickly restore service to boilers rendered inoperative by unprecedented flooding in a 500-unit apartment building.

Restore Heating and Hot Water to Residents After a Storm

Congressional Towers Apartments, located in Rockville, Maryland, is a two-tower, high-rise, 500-unit apartment building in the Washington, DC area. The complex’s heat and hot water are served from a central boiler plant.

During an unprecedented rainstorm, a creek behind the Congressional Towers apartment building overflowed due to the excessive stormwater runoff. The water runoff flooded the boiler room in the facility, rendering the units inoperative. The building sought immediate assistance, and a team of experts from ACI was mobilized to respond to the situation.

The boilers responsible for supplying heat and hot water to over 500 apartment units were rendered inoperable, potentially causing a significant disruption to the residents. This was a serious issue, given that the storm happened just before the cold seasons in Washington, DC, and the equipment was damaged beyond repair. The submerged boilers had to be replaced, and immediate action was required to restore heating and hot water services to the residents.

The boilers responsible for supplying heat and hot water to over 500 apartment units were rendered inoperable, potentially causing a significant disruption to the residents. This was a serious issue, given that the storm happened just before the cold seasons in Washington, DC, and the equipment was damaged beyond repair. The submerged boilers had to be replaced, and immediate action was required to restore heating and hot water services to the residents.

Solution

ACI immediately mobilized their emergency response team and brought emergency pumps to remove water from the boiler room, generators to supply electricity to the building, and mobile boiler units to supply the building with heat and hot water. ACI removed the damaged equipment that was underwater, reconfigured the piping system, and replaced the boilers that supply heat and hot water. The project involved all new insulation, all-new electricals, and an integrated control system to ensure efficient and reliable functioning of the equipment.The ACI team brought our full suite of solutions to get the building back online and mitigate the impact of the incident under extreme weather circumstances. The first priority was to implement a temporary solution to minimize any disruption to the tenants, and subsequently, the team repaired damaged infrastructure and replaced the inoperable boilers. The challenges of restoring the heating and hot water systems were complex, but through their concerted efforts and expertise, ACI replaced the equipment, and the systems were reinstated, ensuring the uninterrupted provision of services to the tenants.

Beacon Capital Partners

Across USA

Solar Rollout

Global Facility Solutions (GFS) provided expert-level project management and construction oversight for a large-scale Solar PV initiative across Beacon Capital Partners’ commercial building portfolio throughout the United States.

Renewable Energy Solutions: Nationwide Solar PV Implementation

Project Objectives

- Implement green energy sustainability technologies across multiple property locations

- Navigate different incentive options and solar organizations available in various U.S. regions

- Assess feasibility of solar photovoltaic technology installations at each site

- Create a phased implementation plan to benefit both Beacon and their tenants

Scope of Work

- Perform expert-level project management and construction oversight

- Conduct feasibility studies for solar PV installations at multiple sites

- Develop a phased implementation plan

- Navigate regional incentive options and solar organizations

- Oversee construction and implementation at various property locations

Solutions

Comprehensive renewable energy consulting services, including:

- Tailored solar PV solutions for each property, utilizing available roof space or incorporating solar car ports

- Expert navigation of regional incentives and solar organizations

- Development of a phased implementation plan to manage the large-scale project effectively

- Ongoing project management and construction oversight

- Continuous evaluation and expansion of the solar implementation program

GFS’s expertise in renewable energy solutions is enabling Beacon Capital Partners to successfully implement a large-scale Solar PV project across their nationwide portfolio, significantly advancing their sustainability goals and providing long-term benefits to both the company and its tenants.

Results By the Numbers

- Estimated generation of over 6 million kilowatt-hours for use at property locations

- Multi-year implementation timeline, starting in 2023

- Multiple property locations across the United States